Home Oil Skimmer

Oil Skimmer Manufacturers in India, Suppliers & Distributors in India

Sunshine Technomech is one of the leading-top Oil skimmer Manufacturers, Suppliers & Distributors in India, We offer premium range of high-performance oil skimming solution systems engineered for efficient oil-water separation in industrial applications. Our Oil skimmers are designed to handle divers range of machines includes tool coolant systems, wastewater treatment plants and metal processing units.

Information about Industrial Oil Skimmer

We are topmost Oil Skimmer Manufacturers in India, Our offered Oil Skimmer system is Specially designed to remove floating oil or grease from the surface of a liquid, primarily water or oil. Oil Skimmers also known as Oil Skimming Equipment has many types like Disc Skimmers, Drum Skimmers and Brush Skimmers, Suction Skimmers which is used in different industries according to the application areas.For bulk orders and customized requirements check our oil skimmer product specification.

Types of Oil skimmer

We are leading Oil Skimmer Manufacturers in India, offer high-quality solutions for removing oils. We provide following types of Oil skimmer

- Disc Type Oil Skimmer: This kind of skimmer is connected with multiple types of discs and submerged in the liquid, and it attracts oil. When the disc rotates, it passes through a scraper mechanism that removes the oil. We have connected high-speed rotational systems and waste separation systems to increase productivity and reduce unwanted waste. These are highly used in steel manufacturing, paper mills, and automotive plants.

- Drum Type Oil Skimmer: This oil skimmer has a simple mechanism, and it uses a rotating drum that attracts oil; this oil sticks to the drum’s surface and is scraped off as the drum rotates at higher speed. Our modern type of drum-type oil skimmer has accurately controlled drums and durable coatings on the outside surface. These coatings can resist any kind of corrosion and wear and give longevity to the oil skimmers. All types of oil skimmers are suitable for chemical plants and offshore oil platforms.

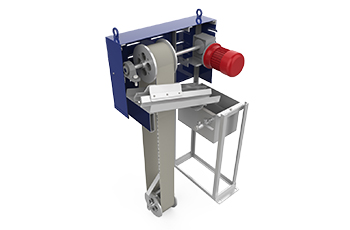

- SS Slat Chain Type Oil Skimmer: These skimmers have a strong quality stainless steel slat chain, which drags through the surface and can collect the oil. The collected oil is transported into a separation zone. These oil skimmers are made with high-quality stainless steel, which is more durable and coated with advanced coatings and used in multiple types of applications, such as heavy industries and large oil volumes mixed with slurry.

Technical Specifications of Oil Skimmer

For more information about our Oil skimmer manufacturers in India, we have mentioned below a technical sheet such as:

| Type | Oil Removal Rate | Belt/Disc/Drum Size | Material of Construction | Motor Power (kW) | Operating Temp (°C) | Max Viscosity (cSt) | Weight (kg) | Applications |

| Disc Type Oil Skimmer | 50–500 L/h | Disc Dia: 300–1200 mm | Polymer, SS | 0.5–2.0 | 5–120 | 2000 | 20–50 | Industrial tanks, offshore |

| Drum Type Oil Skimmer | 20–1,000 L/h | Drum Dia: 100–600 mm | Aluminum, SS | 0.5–3.0 | -5–80 | 2500 | 30–100 | Marine spills, large areas |

| SS Slat Chain Skimmer | 10–300 L/h | Chain Width: 80–200 mm | Stainless Steel | 0.5–2.0 | 10–150 | 3000 | 50–120 | Steel plants, oil pits |

Features of Oil Skimmer

Being the best Oil Skimmer Distributors in India, all types of our oil skimmers are equipped with multiple features inside and give various benefits such as:

- Smart Monitoring and Control Systems: These all types of skimmers are integrated with new technological updates such as Iot sensors. These sensors help to maintain the performance in real-time monitoring of oil levels, and AI-powered algorithms can adjust the skimming speed and environmental factors.

- Advanced Oil Collection Materials: Due to advanced technologies, these skimmers can reduce the waste, and nanomaterials and hydrophobic coatings can maximize oil adhesion while repelling water. These modern mechanisms of our skimmer are more helpful for use in metalworking industries and power plants.

- Energy-Efficient and Eco-Friendly Design: Our all types of oil skimmers are made with eco-friendly designs, and these can also be used with solar-powered operations. We have used biodegradable materials while manufacturing these oil skimmers and support environmental goals by reducing carbon footprint.

- Adaptive Systems for Dynamic Conditions: These oil skimmers are controlled with AI systems for making smooth adjustments in oil levels, flow rates, and contamination types. This system can improve the overall efficiency and improve the consistency when the contamination factor fluctuates.

Application of Oil Skimmer

- Excluding oil from industrial waste water machines.

- Cleaning oil spills in marine environments.

- Skimming oil from machine coolant tanks.

- Maintaining lubrication oil purity in equipment.

- Removing oil contaminants in food processing plants.

- Treating oil-contaminated groundwater and runoff water.

- Managing oil spills in marine vessel operations.

- Recycling oil from metalworking machining processes.

- Controlling oil discharge in chemical manufacturing facilities.

- Recovering waste oil from power generation plants.

We are leading Oil Skimmer Manufacturers, Suppliers & Distributors in India, Sunshine Technomech offer the best quality oil skimmer with high oil removal efficiency, cost-effective solutions, and industry-specific models tailored for diverse applications. We have used multiple types of new technological updates in these oil skimmers for giving more performance. For more information, contact us today

Related Searches

Oil Skimmer Manufacturers in Pimpri, Oil Skimmer Manufacturers in Chinchwad, Oil Skimmer Manufacturers in Bhosari, Oil Skimmer Manufacturers in Chakan, Oil Skimmer Manufacturers in Talegaon, Oil Skimmer Manufacturers in Ranjangaon, Oil Skimmer Manufacturers in Jejuri, Oil Skimmer Manufacturers in Kuruli, Oil Skimmer Manufacturers in Nigdi, Oil Skimmer Manufacturers in Pirangut, Oil Skimmer Manufacturers in Kurkumbh, Oil Skimmer Manufacturers in Alandi, Oil Skimmer Manufacturers in Wagholi, Oil Skimmer Manufacturers in Khed, Oil Skimmer Manufacturers in Baramati, Oil Skimmer Manufacturers in Kasarwadi, Oil Skimmer Manufacturers in Akurdi, Oil Skimmer Manufacturers in Talwade, Oil Skimmer Manufacturers in Chikhali, Oil Skimmer Manufacturers in Hadapsar